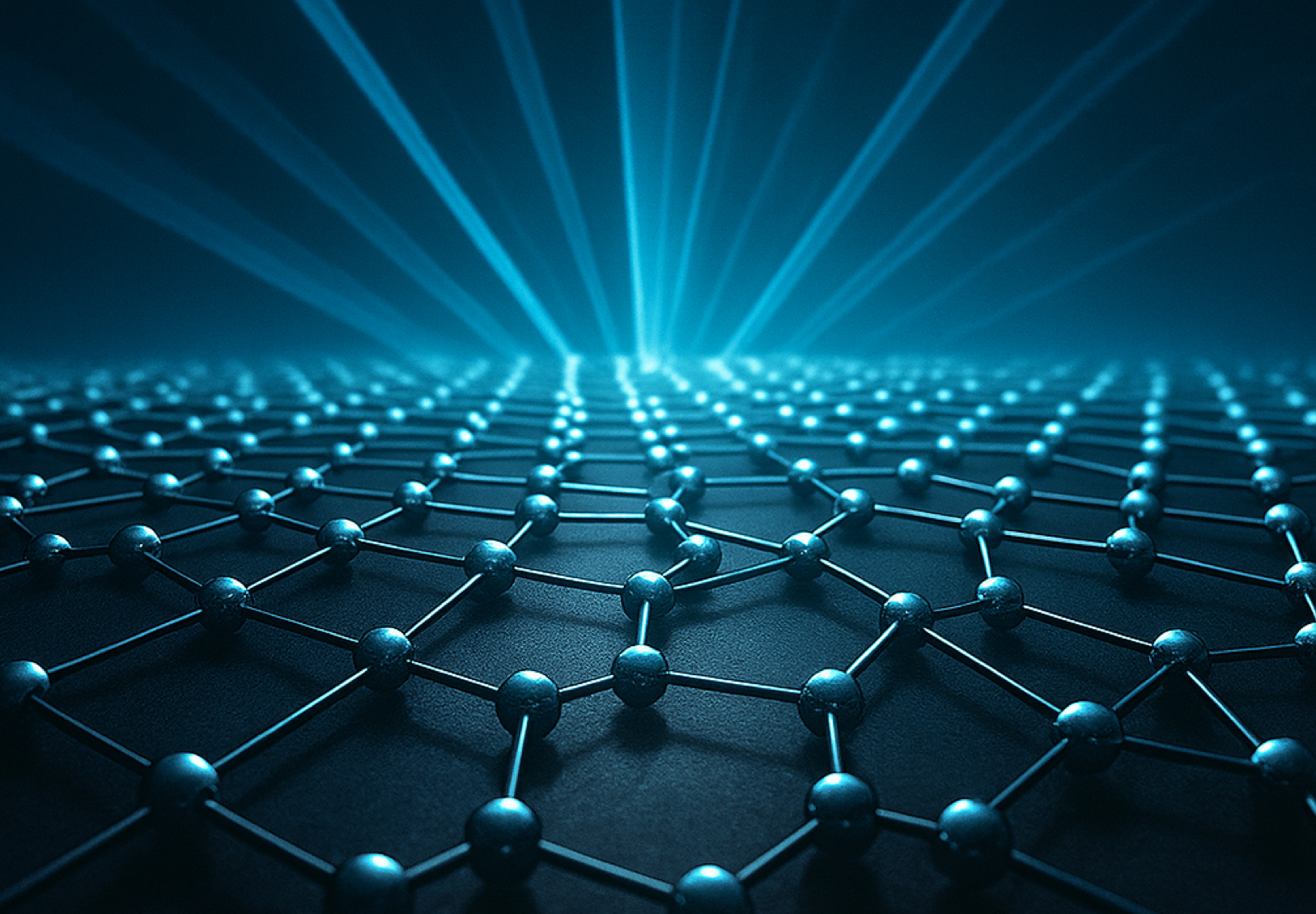

Graphene isn’t science fiction anymore — it’s entering factory floors, energy grids, and product lines around the world. This article explores how graphene will transform key sectors like energy storage, mobility, electronics, and materials science over the next decade — and what businesses should do today to prepare for its industrial-scale impact.

1. From Lab to Line: Graphene Goes Industrial

For years, graphene was hyped as a “wonder material” — but with limited real-world impact.

Why? The gap wasn’t in the material’s potential, but in its scalability.

Today, that’s changing.

Thanks to advances in production technology — such as chemical-free, modular systems like the AT800 Series — high-purity graphene is now being manufactured efficiently, cleanly, and at industrial scale.

This shift is unlocking commercial opportunities in industries that demand both performance and precision.

2. Energy Storage Will Lead the Adoption Curve

Graphene’s unique properties — including high conductivity, thermal management, and surface area — make it a natural fit for batteries and supercapacitors.

By 2030, we’ll likely see:

-

Faster-charging electric vehicles

-

Longer-lasting grid-scale storage for renewables

-

Smaller, lighter batteries for mobile electronics

Companies investing in energy systems that integrate graphene early will gain competitive advantages in both cost and performance.

3. Lightweight Composites & Mobility Materials

Aerospace and automotive sectors are under constant pressure to cut weight and boost efficiency.

Graphene-reinforced composites offer:

-

Greater strength-to-weight ratios than carbon fiber

-

Enhanced resistance to wear and corrosion

-

Improved heat dissipation in high-stress environments

By 2030, we expect graphene-enhanced components to become standard in eVTOLs, aircraft panels, and electric vehicle housings.

4. Electronics & Flexible Devices

As the world moves toward flexible, transparent, and ultra-thin electronics, graphene is one of the few materials that can keep up.

Think:

-

Foldable screens

-

Wearable medical sensors

-

Ultra-sensitive circuit layers

The ability to conduct electricity at the nano level without compromising flexibility makes graphene a foundational material for future electronics.

5. What Businesses Should Do Today

Industries that want to benefit from graphene’s rise can take proactive steps now:

✅ Audit your materials – Where are you limited by weight, conductivity, or durability?

✅ Explore pilot projects – Partner with companies like Loginns to test real-world applications

✅ Secure a supply – Evaluate scalable production methods (like the AT800 Series) to integrate graphene into your value chain

✅ Think beyond cost – Focus on performance, longevity, and sustainability gains

Conclusion

By 2030, graphene will no longer be “emerging” — it will be expected.

The businesses that act today will not only stay ahead — they’ll shape what’s next.